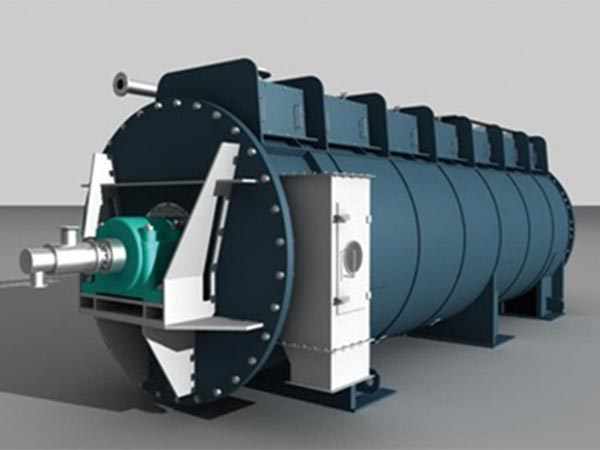

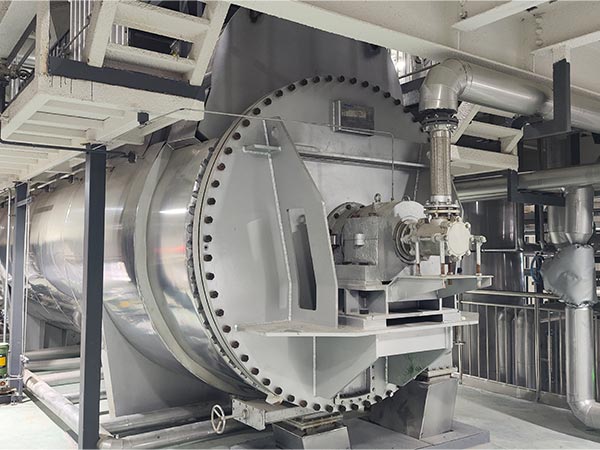

Horizontal Type Dryer

Horizontal Type Dryer

Indirect drying, low oxygen concentration, little flue gas Large evaporation area, small floor space. Low revolving speed,minimum wear and breakage.

Extra Features

- High Efficiency & Energy Savings

- Precision Engineering & Long-Term Durability

- Industrial-grade stainless steel and corrosion-resistant materials for long-lasting durability

- Increase production capacity through high-speed and automated processing

- Heavy-duty components that withstand extreme industrial environments

Available Raw Materials

Environmental Protection Industry: Sludge(Moisture<85%)Food Industry: Plant Protein Animal Protein.

Heat Source

Medium or Low Pressure Steam/Conduction Oil

Horizontal disk dryer is a kind of high-efficiency continuous vacuum drying equipment developed by CHEMSTA for drying high moisture content materials.

Wet materials are fed into the dryer from the inlet and gradually advanced between the shell and the hollow shaft and heating disc, the steam transmits heat through the jacket, the hollow shaft and the hollow disc welded on the shaft, and the materials are indirectly heated and dried, and the water vapor produced gathers in the dome of the dryer, and it is extracted out of the dryer by the vacuum pump.

Horizontal disc dryer mainly consists of stator (i.e. outer cylinder), rotor (shaft tube with heated disc), power system and steam heating system.

(1) Stator: Horizontal cylindrical cylinder with outer jacket, the upper part is semi-circular vault. The jacket is fed with saturated steam, there is a condensate outlet at the bottom of the jacket, there is a mixed vapor outlet at the top of the vault for discharging the evaporated mixed vapor, and there is a clearing device inside the vault for self-cleaning of the heated disc.

(2) Rotor: It consists of a hollow shaft tube and several sets of heating discs welded on the shaft tube. The shaft tube is fed with saturated steam and distributes the steam to each heating disk. Condensate and non-condensable gas are discharged from the shaft end through a rotary joint. The outer edge of each heating disk is equipped with flat scraper and inclined scraper, the flat scraper is used to turn the material, so that the material and the heating disk contact more fully, the inclined scraper is used to push the material, so that the material moves slowly along the cylinder to the direction of the outlet. The drying of the material is through saturated steam to the shaft tube and disc heating, and make it fully contact with the material for heat exchange and then make the material in the wet medium volatilization, and then discharged through the mixed steam outlet. The rotor rotates under the driving force of the power system, and the rotating speed can be adjusted according to the needs.

(3) steam heating system: by the rotary joints, metal hoses, traps, shut-off valves, ball valves, steam separator, etc., the system to ensure that the shaft tube and disk is always full of saturated steam, and to ensure that the condensate is discharged smoothly.

Features:

(1) Indirect drying, low oxygen concentration, less exhaust gas. The whole drying process is completed under vacuum and low temperature environment, which is suitable for heat-sensitive materials.

(2) Through the shell jacket and the inner heating disk heating at the same time, a single device heating area, high thermal efficiency, equipment covers an area of small.

(3) It is equipped with stirring device, which makes the material form a continuous and uniform state in the cylinder body, and further improves the uniformity of the material’s heating and the effect of heat and mass transfer.

(4) Reasonable and advanced design, easy installation and commissioning, can be adapted to various conditions of installation.

(5) Reduce the labor intensity of workers and improve the working environment.

Application:

Municipal sludge, industrial sludge, plant protein (soybean protein concentrate), animal protein powder, feather drying, fish meal drying