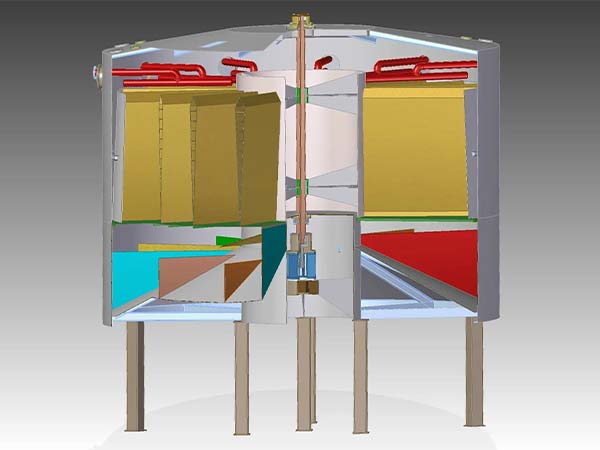

Rotocel extractor

Rotocel extractor

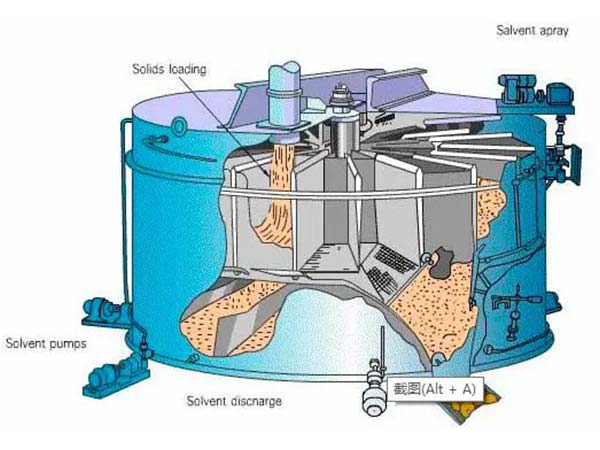

ChemSta Rotocel Extractor is a continuous combined type oil extractor. The rotor consisting of material cells rotates around the main shaft for one cycle to complete the extraction process. Rotocel extractor is the most widely used edible oil extraction equipment

Extra Features

- High Efficiency & Energy Savings

- Precision Engineering & Long-Term Durability

- Industrial-grade stainless steel and corrosion-resistant materials for long-lasting durability

- Increase production capacity through high-speed and automated processing

- Heavy-duty components that withstand extreme industrial environments

ChemSta Rotocel Extractor is a continuous combined type oil extractor. The rotor consisting of material cells rotates around the main shaft for one cycle to complete the extraction process. Rotocel extractor is the most widely used edible oil extraction equipment, suitable for small and medium oil extraction plant. Rotocel extractor is suitable for the oil extraction of peanut, rapeseed, cottonseed, sunflower seed, sesame, corn germ, camellia seed, flax seed, castor seed, soybean, rice bran, safflower seed, palm fruit cake, palm kernel cake, copra, grape seed, evening primrose seed, etc. The extractor is especially suitable for extraction of various pre-pressed oil cakes. Rotocel extractor is also used for extracting capsicum red pigment.

Advantages:

- Simple structure, easy operation, and maintenance.

- Adopt stainless steel stationary grid, with an additional horizontal grid to prevent backflow of thick miscella into the material cells. The grid gap has a self-cleaning effect and is free of clogging.

Adopt gear-rack drive, unique rotor balancing design, low rotating speed, small power consumption, stable and reliable operation without noise, low failure rate. - The feed system automatically adjusts the rotating speed of the closed-air aspirator and main engine depending on the incoming amount, so that the materials in the buffer bin can maintain a certain level, which is good for the formation of negative micro-pressure inside the extractor and reducing the leakage of solvent vapor.

- Adopt advanced miscella circulation design, good for reducing the input of fresh solvent, reducing residue oil in meals, increasing miscella concentration, and saving energy through reducing the amount of evaporation.

- High material layer, good immersion effect, good filtration effect, low fines content in the miscella, improving the quality of crude oil and reducing the scaling of evaporation system.