Rice Bran

Rice Bran Processing Production Line(Preparation and solvent Extraction)

The purpose of preparation is to get a portion of oil by mechanical pressing while providing pressing cakes for extraction plant. The processes: Cleaning, Weighing, dehulling, Kernel and Hull Separation, Softening, Flaking, Cooking, Pressing, Oil Residue Separation, Solvent Extraction.

Pressing

1. Cleaning, Metering:

Major Devices: flat classifying screen, online meter and magnetic separator for iron removal

2. Condition, Extruding, Cooling:

Major Devices: Horizontal drum rotary conditioner, feeding conveyor, Air Lock Valve, Counterflow Cooler

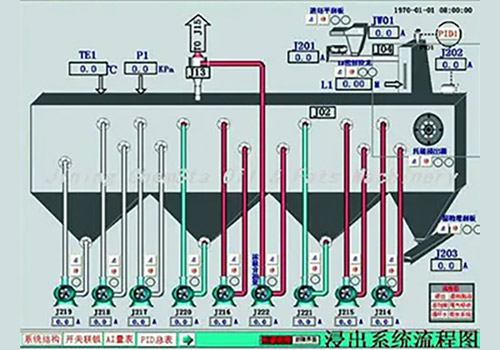

Solvent Extraction

1. Oil Extraction:

Customers can choose rotocel extractor or drag chain extractor based on their requirements. For different raw materials, the grid tray clearance and grid tray arrangement will be properly adjusted to ensure that the oil residues in the seed meal is at a minimum. In addition, liquids in the seed meal will be completely drained, contributing to a minimum solvent content. As a result, the burden on the desolventizing device in the sequential process is significantly lowered, reducing the steam consumption.

2. Meal Desolventizing:

DTDC consists of the pre-desolventizing layer, the heat exchange layer, desolventizing layer, heat recovery layer, drying layer, and the cooling layer. Material levels in each layer are automatically controlled, and the full utilization of secondary steam reduces steam consumption. Mixed steam is used to heat miscella after meal foam removal, which further saves energy The process features a thorough desolventizing, light yellow meal, complete passivation of anti-nutritional factors and requires only a short time for high temperature desolventizing and a low loss of meal NSI.

3. Oil Filtration:

Oil Filtration is designed to filter out solid impurities prior to miscella evaporation. Devices used in this process include a high pressure delivery pump, centrifugal separator, and a filter with a slagging function. The optimum filtration effect is achieved by a combination of centrifugal separation precise filtration processes. Because the filter is able to automatically remove slag, no manual operation is needed.

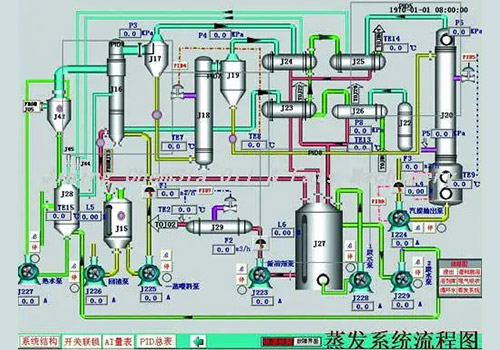

4. Evaporation System:

Equipment in evaporation system involves evaporator, disc stripping tower, flash separator, heat exchanger, and vacuum unit. Under vacuum and negative pressure condition, solvent in the miscella will be evaporated and separated by rising film evaporation and direct stripping process. After desolvation, bright color leached oil will be obtained. To ensure the system stability and reliability, an automatic PLC control system is used to control the evaporating temperature and vacuum level. Both mixed steam and power steam for the vacuum pump will be used for evaporation. Heat transfer and mass transfer between the cool and hot medium furthers reduces steam consumption, In addition, lipid oxidation can be prevented as well.

5. Solvent Condensation and Recovery System:

Solvent condensation and recovery system consists of condenser and cool water system. Under vacuum and negative pressure conditions, the condensable solvent steam is condensed into liquids for cyclic utilization through a dividing-wall heat transfer. Multiple pass structure of the condenser and proper settings of flow rate and speed of circulating water will greatly improve efficiency of the condensation and separation, while also reducing investment capital and operating costs. In addition, tube plates, baffle plates, and heat exchange tubes are all made of stainless steel S30408, which facilitates cleaning and withstands corrosion . Moreover, great condensation effect and long service life can be fully ensured.

6. Paraffin Absorption System:

Paraffin absorption system consists of paraffin absorption column, paraffin desorption column, heat exchanger, storage tank, circulating pump, explosion-proof fan and fire protector. This absorption system is able to recycle more than 98% of solvent in the exhaust gas, which reduces the solvent gas loss and protects the environment. The system makes use of food-grade liquid paraffin to adsorb the solvent gas mixed in exhaust gas. Solvent steam is distilled and separated with the help of superheated steam, and the solvent steam obtained through this process will be recycled through condensation. To ensure stable absorption efficiency and system reliability, automatic controls are used to control important parameters such as flow rate, temperature and pressure.

7. Water & Solvent Separation Section:

This system consists of solvent-water separator, boiling tank,and fresh solvent pump. It separates water from solvent based on the principle that water repels solvent and two liquid layers will be formed in their mixture. To ensure stability and reliability of the system, automatic control devices are applied to control important parameters such as flow rate, temperature and material level.

Automatic Control System

In CHEMSTA production lines, we make use of Siemens PLC control system, which is one of mainstream automatic control systems in today`s industry. The efficient, stable and advanced DCS control system consists of operation station, control station and communication network. We utilize high-speed and large-capacity S7-400 series PLC at the control system, large-screen LCD at the operation station, WINCC 7.0 industrial control software as monitoring software and PROFIBUS filed bus network for communication.