Soybean Protein Isolate(SPI)

Soybean Protein Isolate (SPI) Production Line

CHEMSTA makes use of Alkali-Solution and Acid-Isolation Extraction process to separate fiber and protein from low-temperature soybean flakes. Then, separated protein solids go through high pressure homogenization, high temperature sterilization and spray drying to produce protein isolates.

SPI Application

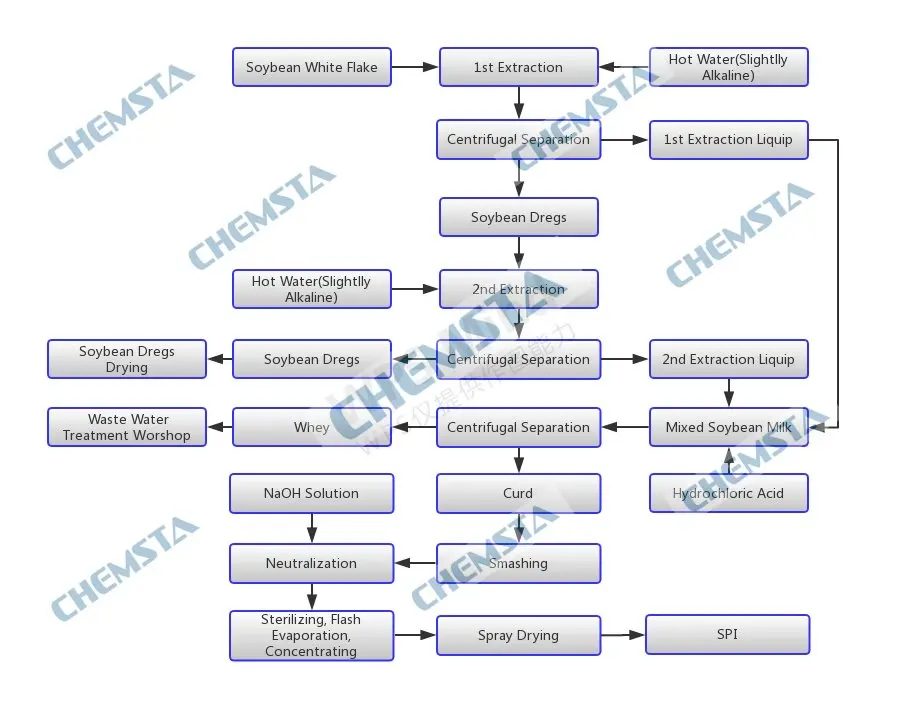

SPI Process

1. Process Workflow:

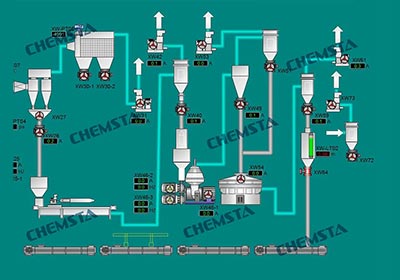

2.Raw material receiving & storage section:

Raw materials (soybean white flake) are transported to the workshop unloading platform, then poured into the hopper and are elevated into the day warehouse through a bucket elevator. The soybean meal should be uniformly distributed to the Z-type scraper by the frequency-feeding auger after deironing by the magnetic separator, and then elevated into the 1st extraction tank by the scraper. The feeding-system auger is equipped with automatic control. It is operated by the personnel in the central control room and also set up with a process chain and a security chain.

3.SPI Extraction Section:

The soybean meal out of the raw material warehouse enters CHEMSTA 1st extraction tank after removing iron and impurities. At the same time, water from the hot water tank is added into the extraction tank, and a certain concentration of diluted alkali solution is added on the pipeline connected to the extraction tank, thus adjusting the pH value of the material in the extraction tank. The temperature of the material liquid in the reaction tank is controlled by controlling the temperature of the process water added. After reaction for a certain time, the material enters the 1st extraction centrifuge for separation. The liquid phase enters the soybean milk tank, and the solid phase enters the 2nd extraction tank. Hot water and diluted alkali solution should be added into the 2nd extraction tank for two – step extraction. The two – step extraction time should be controlled reasonably. The material which has undergone two – step extraction should be pumped into the 2nd extraction centrifuge. The liquid phase flows into the soybean milk tank, and the solid phase (i.e. soybean dregs) should be conveyed into the soybean dregs discharging plant. The wet soybean dregs can be sold directly or after drying.

4.Acid Precipitation Section:

The mixed soybean milk in the soybean milk tank is conveyed into the CHEMSTA acid precipitation tank, and diluted hydrochloric acid solution is added to adjust the pH value of the solution to about 4.5, so as to make the protein precipitate at the isoelectric point. The precipitation time is controlled by the volume of the precipitation tank. After centrifugal dehydration with a horizontal centrifuge, the liquid phase, which is whey water, is pumped into the waste-water treatment plant. The mixture of the solid phase and a certain amount of process water enters the smashing tank. The granular material in the smashing tank is cut into paste-like protein slurry, and then the paste protein slurry is pumped into a plate heat exchanger for cooling, and finally enters the neutralization tank.

5.Neutralization, Homogeneous,Sterilization, Flash Evaporation,Dry Section:

In order to improve the functionality of the final product, it is necessary to add a certain amount of NaOH solution to curd protein which is separated from the acid precipitation section, and then stir the mixture to adjust the pH value of the curd.

The well-stirred protein slurry should be homogenized under a certain pressure condition, making it small uniform particles, and then the homogenized soybean protein isolate slurry is conveyed into the sterilizer for high-temperature instantaneous sterilization.

The sterilized protein slurry should be conveyed into the flash evaporation tank for CHEMSTA-style flash evaporation and dehydration and removing beany flavor, then pumped into the drying section by a high-pressure homogenizing pump.

The material which is pumped into the drying tower by a high-pressure pump should be atomized by a spraying nozzle and also conduct parallel flow heat exchange with hot air to complete dehydration and drying.

The well-stirred protein slurry should be homogenized under a certain pressure condition, making it small uniform particles, and then the homogenized soybean protein isolate slurry is conveyed into the sterilizer for high-temperature instantaneous sterilization.

The sterilized protein slurry should be conveyed into the flash evaporation tank for CHEMSTA-style flash evaporation and dehydration and removing beany flavor, then pumped into the drying section by a high-pressure homogenizing pump.

The material which is pumped into the drying tower by a high-pressure pump should be atomized by a spraying nozzle and also conduct parallel flow heat exchange with hot air to complete dehydration and drying.

6. Major Equipment:

Rising conveyor, magnetic separator, scale,CHEMSTA extractor, high pressure pump, separator, quantifying pump for PH value, neutralization tank, flash tank, sterilizer, homogenizer, spray drying tower, classifying screen, heat exchanger, air heater, vacuum system, protein collector, protein packing system, elctrical control equipment and other auxiliary devices

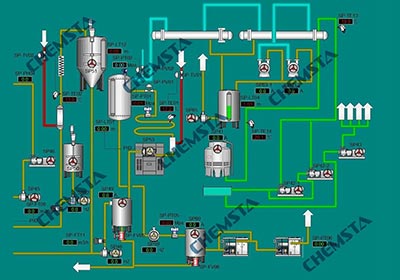

Automatic Control System

CHEMSTA Specialty provides you with cottonseed shelling pretrIn CHEMSTA production lines, we make use of Siemens PLC control system, which is one of mainstream automatic control systems in today`s industry. The efficient, stable and advanced DCS control system consists of operation station, control station and communication network. We utilize high-speed and large-capacity S7-400 series PLC at the control system, large-screen LCD at the operation station, WINCC 7.0 industrial control software as monitoring software and PROFIBUS filed bus network for communication.eatment, cottonseed meal degreasing, dephenolization to produce cottonseed protein. We can supply design, manufacture, installation, commissioning and after-sales work of complete equipment and engineering.