Soybean Protein Concentrate(SPC)

Soybean Protein Concentrate (SPC) Production Line

Ethanol is used to remove alcohol-soluble and water-soluble matter from soya meal, and ethanol is recycled.

Food grade SPC is usually used as an additive in flour-made food and meat products. It is also applied for production of health care products, which contain about 70 percent protein.

Feed grade SPC is applied as a feed additive in particular, which is put in fodder for baby pigs, aquatic livestock, calves or pets.

Introduction

SPC Process

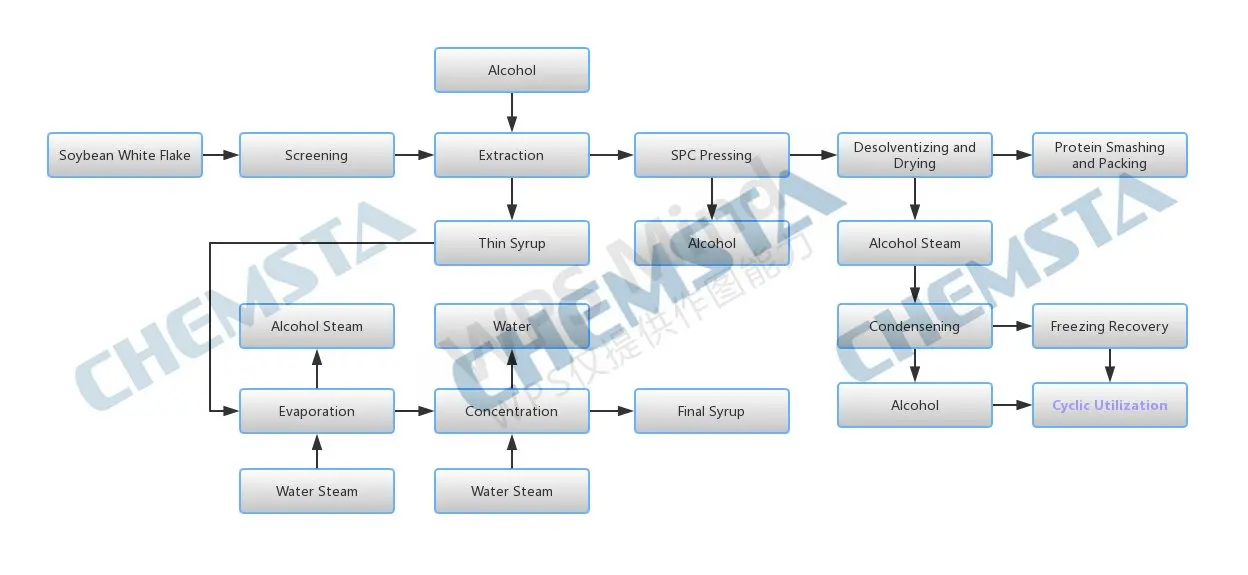

1. Process Workflow:

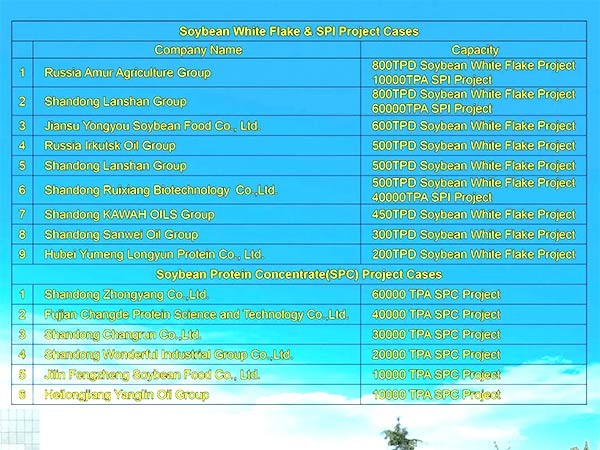

In CHEMSTA SPC production line, edible alcohol is used to extract and separate water-soluble components (mainly soluble sugars) from low-temperature soybean flakes. The resulting soybean product will be extruded, smashed, desolventized, dried and superfinely milled, thus obtaining soybean protein concentrate. The whole production process won’t generate water pollution and air pollution, which is environmentally friendly. CHEMSTA SPC production process will become a prominent method for producing SPC in the future. In China, almost all SPC plants built by CHEMSTA in recent years have a capacity ranging from 10,000 tons per year to 70,000 tons per year.

The process is as follows: Powder is removed from low-temp meal by a grading screen, then the screened meal is conveyed to the CHEMSTA SPC Extractor, and ethanol is used to remove alcohol-soluble and water-soluble matter from soya meal. Through multistage backward immersion and spraying, soluble saccharides are dissolved, and thin molasses is obtained and flows out of the extractor.

After part of the water is extruded from the extracted solid material, it flows into the CHEMSTA Extruder and then goes into the drying machine. Under vacuum, ethanol is removed, the moisture is adjusted, and the product goes to the product warehouse for crushing, measuring, and bagging. Gas out of the dryer flows into the dry fines catcher and condenser successively. The noncondensed gas will flow into the frozen recovery system.

Powder is removed from thin molasses through a cyclone hydraulic separator. After evaporation and concentration, the molasses concentration can reach 47-50%, and almost all the ethanol is removed. If further evaporation is adopted, the molasses concentration will reach above 55%. Oligosaccharide and isoflavone can be extracted from the evaporated molasses. Or the evaporated molasses can be mixed with soya hulls to enhance the nutritive value of the feed as an additive. Ethanol gas flows into the condensing and recycling system.

Powder is removed from thin molasses through a cyclone hydraulic separator. After evaporation and concentration, the molasses concentration can reach 47-50%, and almost all the ethanol is removed. If further evaporation is adopted, the molasses concentration will reach above 55%. Oligosaccharide and isoflavone can be extracted from the evaporated molasses. Or the evaporated molasses can be mixed with soya hulls to enhance the nutritive value of the feed as an additive. Ethanol gas flows into the condensing and recycling system.

2. Major Equipment:

PC Extractor, extruder, horizontal desolventizer, vertical dryer, evaporation and concentration system for syrup, condenser for recycle of ethanol steam, recovery system for exhaust gas, protein conveying and cooling system, protein smashing and packing system, rising conveyor and other auxiliary devices.

Automatic Control System

In CHEMSTA production lines, we make use of Siemens PLC control system, which is one of mainstream automatic control systems in today`s industry. The efficient, stable and advanced DCS control system consists of operation station, control station and communication network. We utilize high-speed and large-capacity S7-400 series PLC at the control system, large-screen LCD at the operation station, WINCC 7.0 industrial control software as monitoring software and PROFIBUS filed bus network for communication.